Learn More About Us

ImanTak Pishro Company

ImanTak pishro , which is one of the subsidiaries of the ITP Holding, with more than four decades of experience in the production of various types of keys, sensors, and electromechanical switches, is one of the leading companies in this field. The company has been able to provide high-quality products to its customers by using modern production methods and utilizing state-of-the-art tools and technologies. With a specialized and experienced team, ImanTak is capable of meeting the needs of its customers in various industries, including automotive. Quality, international standards, and competitive pricing are the three main pillars of this company’s activities.

The growth trend of ImanTak Pishro up to the present day

1368: Establishment of ImanTak Workshop with a focus on producing automotive products, including Peykan brake pedals.

1379 : Obtaining Grade B Certification by Sapco Company in accordance with Sapco 79 requirements.

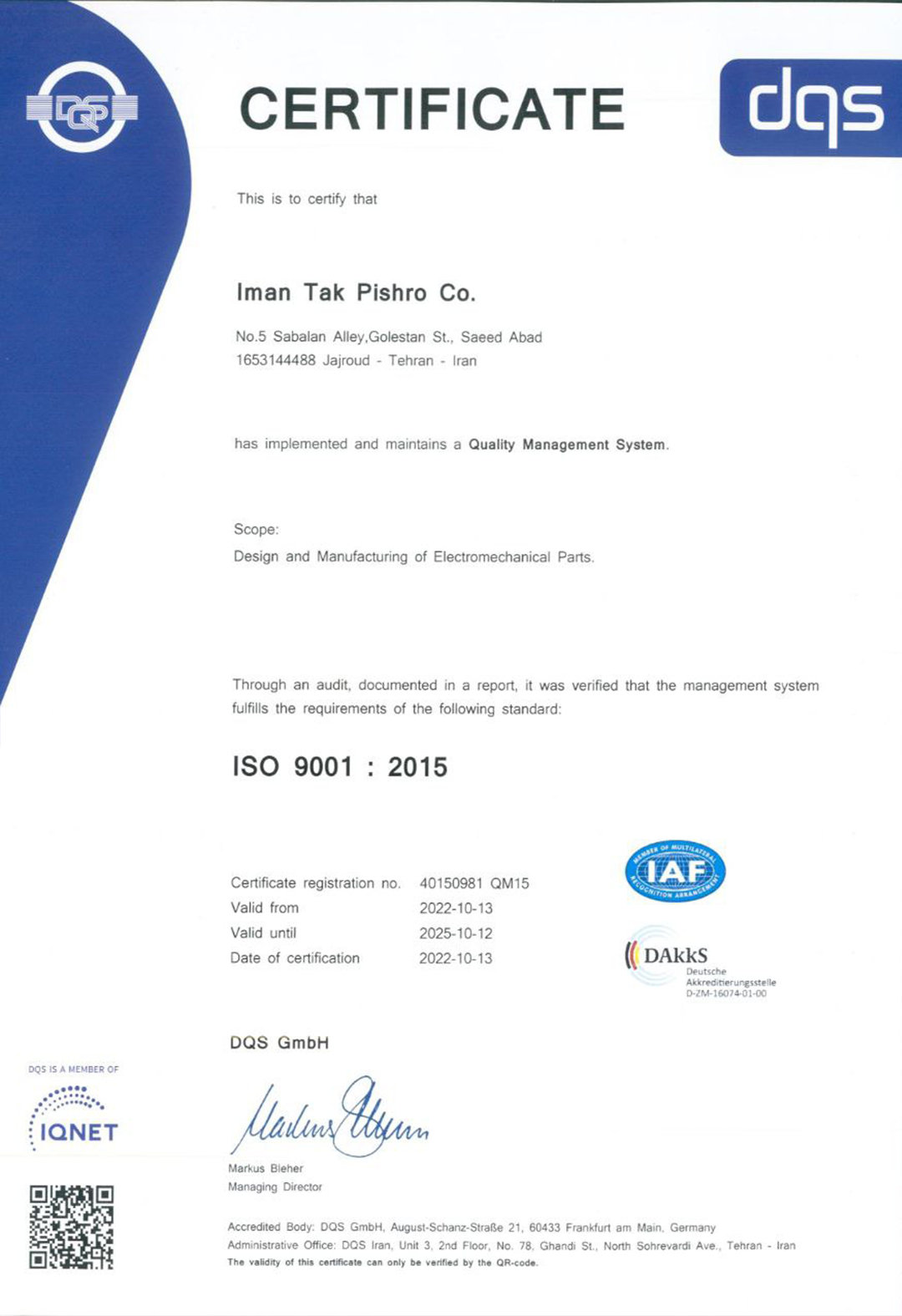

1384 : The registration of a company under the name ImanTak Pishro, marking the official commencement of production activities and the expansion of collaboration with domestic automotive manufacturers. The company has also obtained ISO/TS 16949:2002 standard certification.

1385 : The production of various automotive electromechanical keys, including rear window defrost keys for Peugeot, rear windshield wiper keys for Peugeot, Peugeot flashers, and more.

1388 : Obtaining Grade +B Certification from Saipa Structure Company based on specific requirements of AR8601.

1389 : Obtaining Grade B Certification from Sapco Company based on specific requirements of SSR2.

1390 : Obtaining ISO/TS 16949:2009 standard certification with a focus on product design and development.

Signing a collaboration agreement for the design, construction, and production of automotive components, including Peugeot 206 keys, with a reputable parts manufacturing company in China.

Relocating the factory to Jajrood Industrial Zone and expanding the company's physical space.

1391 : Designing, configuring, and manufacturing automotive thermal sensors, including Peugeot and Pride water temperature sensors, as well as oil pressure sensors for Peugeot and Pride, and more.

1392 : Designing, configuring, and manufacturing window lifter switches for Samand, Peugeot 405, and Peugeot 206 automobiles.

1394 : Expanding sales in the spare parts market by more than one hundred percent.

1395 : Expanding the product range in the family of keys, sensors, and switches from 60 to 90 components.

1396 : Designing, configuring, and manufacturing a car speed sensor for Samand and Peugeot vehicles.

Signing a contract with Ikcap Company for the design and production of dashboard keys and mirror adjustment keys for Peugeot 301, 208, and 2008 cars.

Inclusion in the vendor list of Peugeot France.

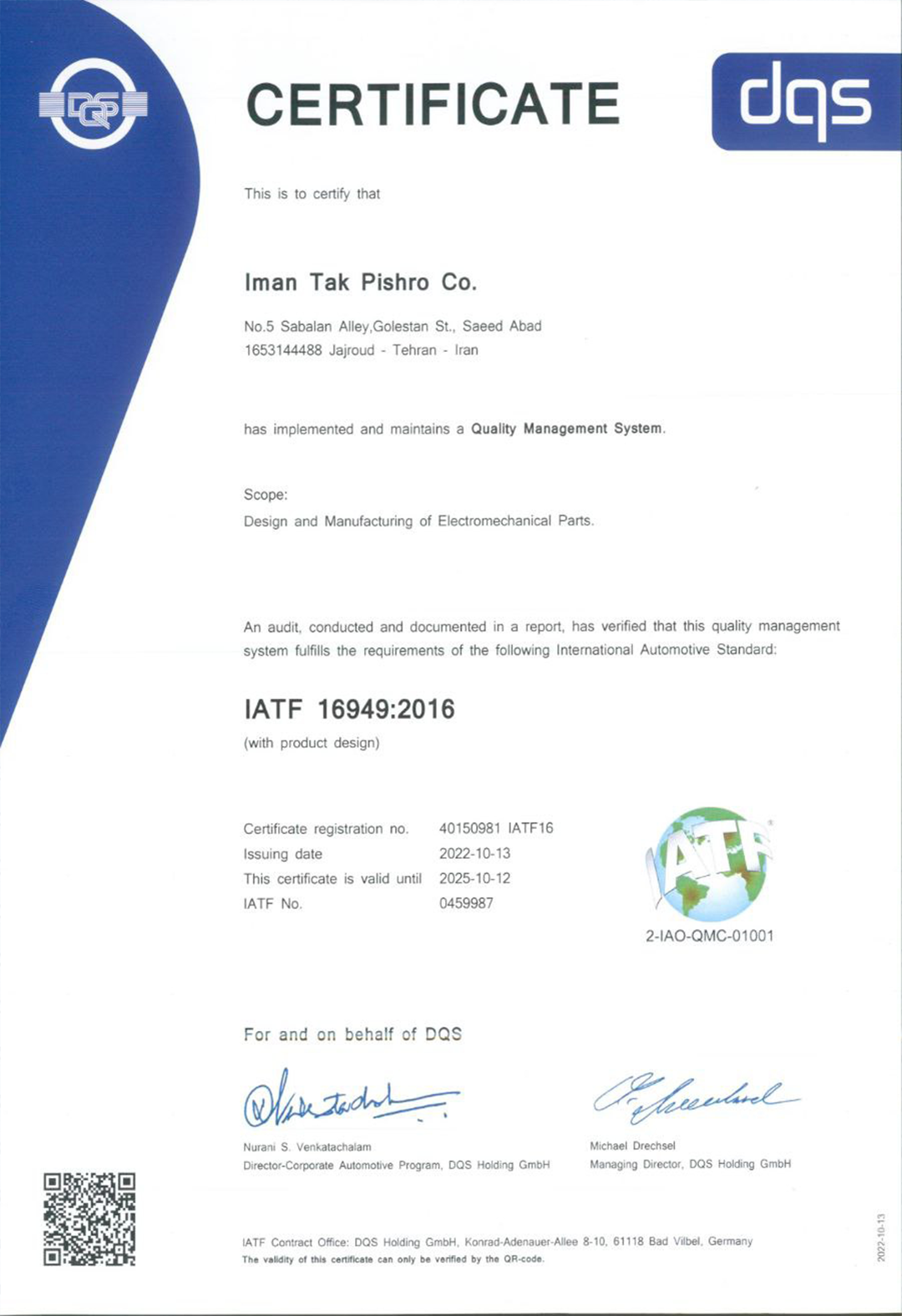

1398 : Obtaining the IATF 16949 standard certification from TUV Germany.

Launching a production line for dashboard keys and mirror adjustment keys for Peugeot 301.

1399 : Designing, configuring, and manufacturing window lifter keys for Peugeot 301 (K132).

Designing, configuring, and manufacturing various types of electromagnetic relays.

Designing, configuring, and manufacturing various high-pressure hydraulic sensors and self-sufficiency in gas cooler sensors for domestically manufactured cars.

1400 : Designing and configuring power window and electric mirror keys for Pars, Dena, Runna Plus, and Tara cars.

Designing, configuring, and manufacturing oxygen sensors.

Designing, configuring, and manufacturing Moto XU7 stepper.

Physical expansion of the production space to 3000 square meters.

1401 : Design and configuration of the roof console keys for Tara.

Design and configuration of the glass elevator keys for Tara.

Design and configuration of the seat adjustment for Tara.

Design and configuration of the glass elevator keys for Soren Plus.

Design and configuration of the Saina and Quick switch bank.

1402: Design and configuration of various interior car horns.

Design and configuration of various micro relays used in the car wiring harness.

Design and configuration of motor rotation sensors.

Obtaining a knowledge-based certificate in the production of laboratory products and services.

Quality policy

Iman Tak Company, a leading player in the production of various electromechanical parts, aims to achieve top-tier reputation in the automotive industry and other sectors. The organization's major goals are outlined as follows:

- Increase sales by expanding the product range and diversifying customers.

- Ensure customer satisfaction by understanding their requirements and expectations and striving to fulfill them.

- Maintain and develop the company's human capital by enhancing their knowledge, motivation, and satisfaction.

- Achieve profitability by reducing costs and reaching zero defects.

Senior management is determined to achieve the above goals by providing the necessary resources and establishing a quality management system based on the 16949:2016 IATF standard. They are committed to creating favorable conditions for developing a culture of excellence and continuous improvement of the integrated management system through the cooperation and participation of employees at all levels of the organization. Therefore, all colleagues are requested to understand, implement, and promote the provisions of this policy in their related work areas.

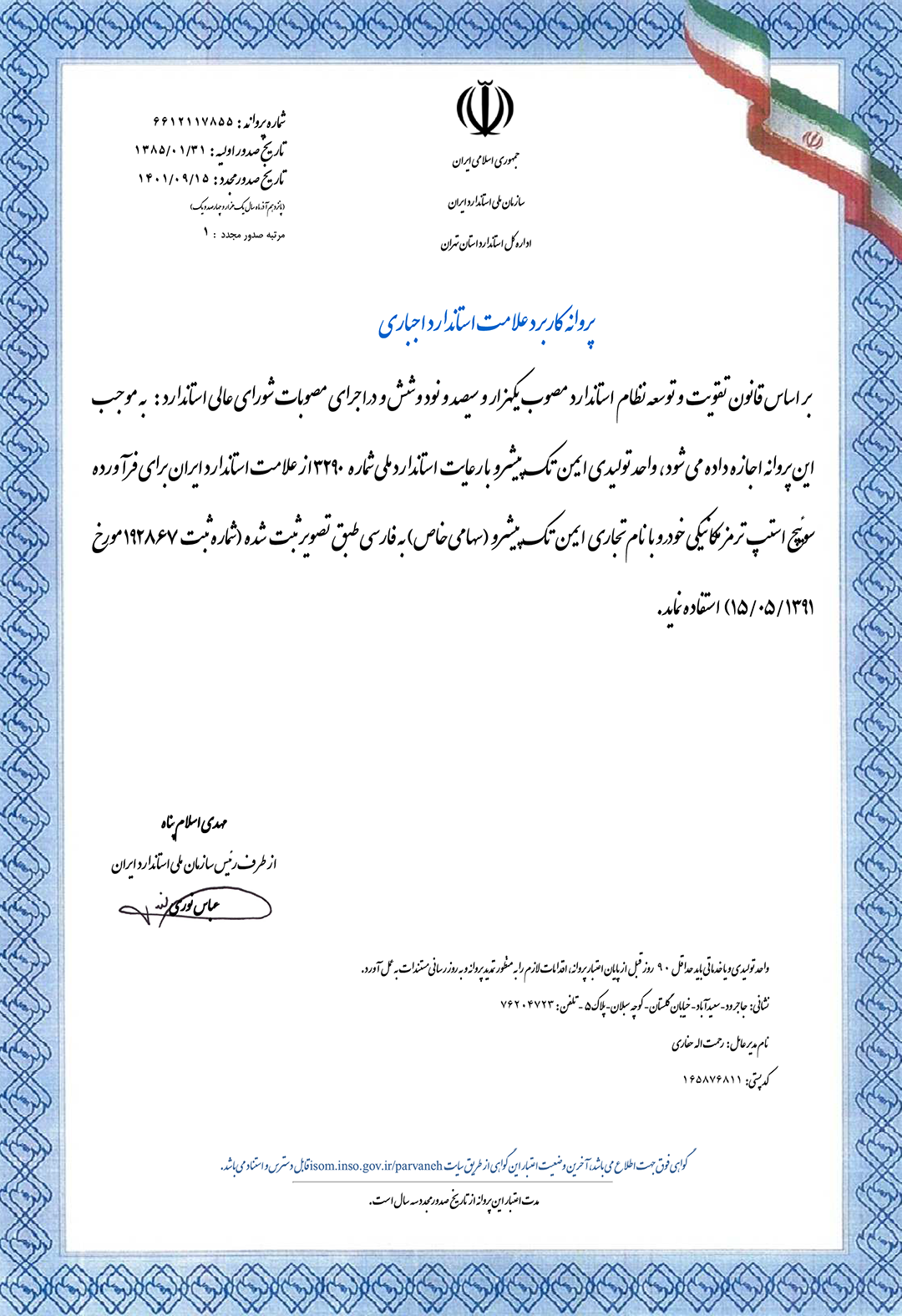

Accomplishments and certificates